一、Simulation Making

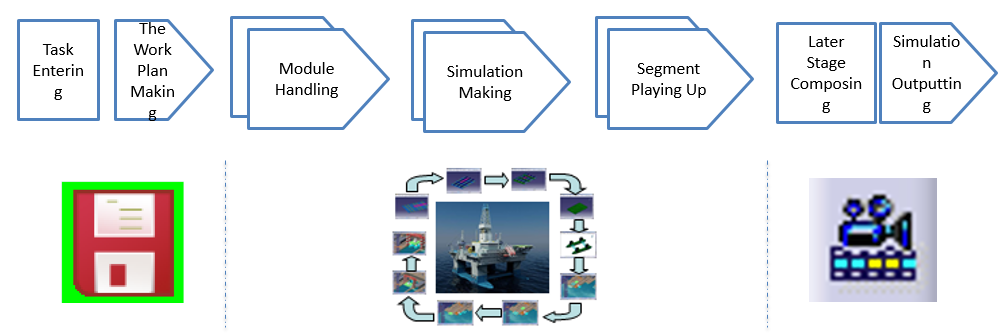

Simulation Making Procedure:

After entering the task, in accordance with the display to make the plan and hold relevant links of movie, output video segment and edit,and add captions and background music, etc.,forming simulation video at last. Using CATIA、3DVIA Composer and 3ds Max to complete all the job for simulation making and module handling .

II Simulation Types and Typical cases

1、Offshore equipment assembly and construction process 3D simulation

Display unique offshore project construction site, equipment, process and construction process visually

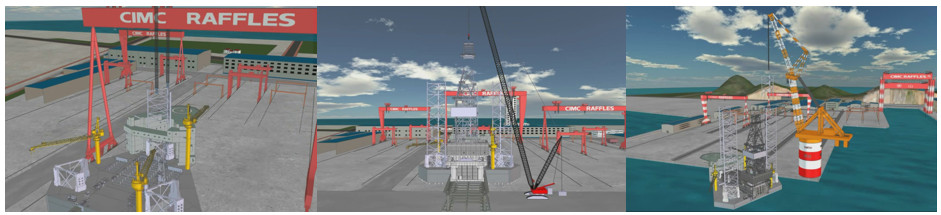

Typical case: JU2000E--jack up drilling platform's construction process

The simulation shows the Long Kou base for JU2000E type jack up drilling platform's unique construction process.

Simulation content:

1. Create 3D model of Long Kou base facilities 2.shipyard roaming 3.block construction 4.vessel erection 5.cantilever construction and Its weight test 6.hull lunching 7. leg erection 8.Inclinding test etc.

2. The key process of the construction of offshore equipment 3D simulation

Complex technology of three-dimensional simulation calibration, calibration workmanship sequence, identify potential risks and to optimize it, formation of the visual guidance document

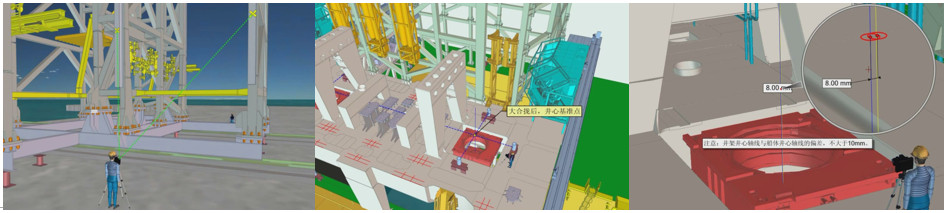

Typical Case: D90 derrick installation solutions and procedure simulation

In this simulation video mainly showed the key procedure which achieved the precision control targets in process of dismantling of transportation of derrick.

Hai Yang base construction stages: 1.derrick foundation manufacture 2foundation alignment measuring 3.Assembly and wielding jig 4. well core pole;

Yan Tai base construction stages : 1.derrick transportation 2. shaft center axle measurement 3. Precision measurement after erection 4. level datum 5. Precision of equipment support block of 6.drilling floor axle measurement 7.floating lifting 8.procession of precision control before hook off

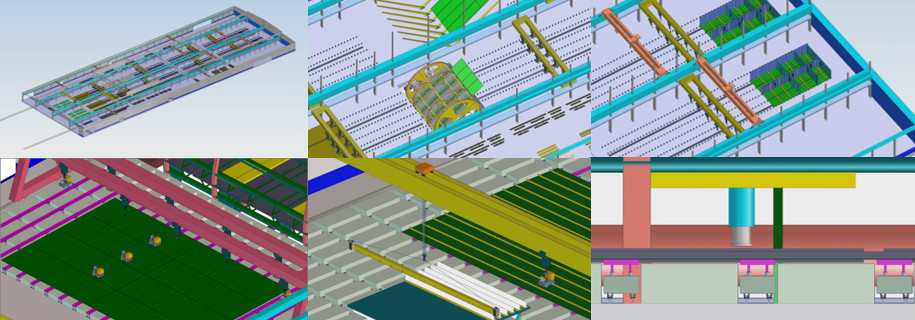

3、3D digital simulation of shipyard and production line

To reach maximum efficiency of producing-process, improve production efficiency and reduce the cost of production line configuration

Typical case:Panel production line planning simulation of base

According to planning to make a simulation,and simulate assembly line production process. Such simulation verified and improved dimensional planning through more visual 3D simulation .

The main content of the 3D simulation : 1. Production line overview 2.edge cutting 3.weilding of jointed plate craft 4. travelling bogie 5.style of skid plate 6.tray 7.in slice.

4、 Market Bidding Programs 3D Simulation

Respond quickly to get bidding plan ,show it to the potential owner visually.

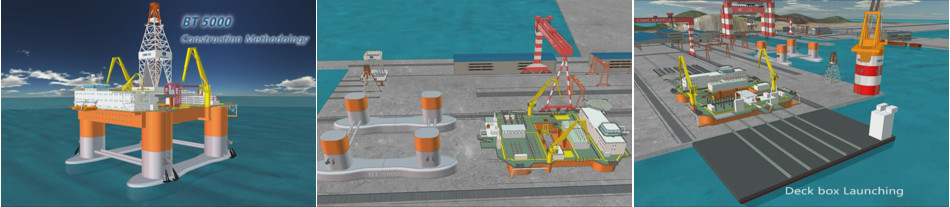

Typical case: BT5000 project bid-building simulation

On the basis of bidding project construction plan simulate whole project construction process, Forming bidding project simulation video.

Video generally include the following main contents:

1.Construction site introduction 2.typical block construction 3.block erection 4.lunching transportation process 5. Special module transport and lifting 6.20000T erection 7.special equipment installation 8.test items 9.Trial and delivery.

5. Ergonomics 3D Digital Simulation

Through 3D simulation to simulate the design of man-machine engineering, examine the rationality of the design, exam and show the feasibility and operability of load project.

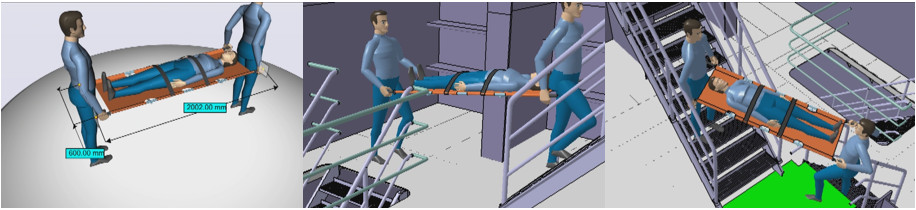

Typical case: GM4D project stretcher transportation simulation of column access.

The simulation mainly exam escape channel design situation of GM4D project column, to simulate whether it is able to let stretcher pass the access or door successfully in an accident, to quickly transport the injured to safe areas.

6、Typical Offshore Equipment Suppositional Roaming& Simulation Display

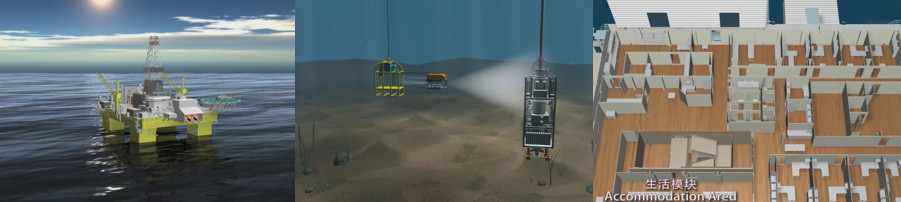

Typical : A typical semi-submersible drilling platform function display emulation

The simulation is mainly show the key tanks of semi-submersible drilling platform, drilling part and ROV, etc. Including following 11 contents:

1. The overall appearance of browsing 2.Main engine room display of slicing 3 the main engine room inside browsing 4.mud pump room display of slicing 5. Mud treatment room browsing;6.living quarter display of layer slicing;7、3D floater display of slicing;8、Thruster Room Skim 9.drilling module review 10.BOP lifting and transferring; 11、ROV transferring and loading。

7、Offshore Products & Shipyard Renderings Design

Typical case:JU2000E、CR600、YCRO、LCRO renderings

Build platform and shipyard emulation models, and put the model in the virtual scene, Make the model look desired artistic effects or tend to be real, form the picture, the final rendering images or add instructions , can be used to improve the design or business promotion.